Changzhou Victory Technology Co., Ltd

Detail Information

Business Type:

Manufacturer

, Distributor/Wholesaler

, Trading Company

, Seller

No. of Employees:

100~150

Detail Description

Changzhou Victory Technology Co., Ltd is a leading manufacturer of high-quality nickel alloy products. We offer a wide range of solutions, including pipes, fittings, bars, sheets, and wires, specializing in grades such as Monel, Inconel, Incoloy, and Hastelloy. With a focus on innovation and customer satisfaction, we adhere strictly to standard compositions, ensuring consistent quality and performance. Trust Victory as your reliable supplier for all your nickel alloy needs.

Driven by our commitment to excellence, we have obtained ISO9001 international quality management system certification and SGS certification. Our customer-centric approach allows us to understand and meet the unique requirements of clients across industries. Experience the reliability, quality, and expertise that set us apart. Choose Changzhou Victory Technology Co., Ltd as your trusted partner in the nickel alloy industry.

Changzhou Victory Technology Co., Ltd was established in 2016 and has passed ISO9001 international quality management system certification and SGS certification. Our factory is becoming a high-tech company, specializing in the R&D and production of special alloy materials. The production process includes melting, wire drawing, heat treatment, finishing, and testing.

Main categories: Heating Resistance Wire, Nickel Welding Wire, Thermocouple Wire, Corrosion Resistance Alloy, Thermal Spray Alloy

Why choose us?

1. Market Leader

Top 5 in China's nonferrous metal industry

2. Flexible products

Thousands of product specifications,Meet multiple needs of buyers

3. Low MOQ

Can customize samples

4. Short production lead time,fast delivery of whole cabinet

5. Professional inspection equipment

Before delivery, we will use spectrometers, tensile testers and other professional equipment to conduct a comprehensive inspection of the products to ensure that the goods are qualified for acceptance

6. Professional business team

Quickly responds to customer inquiries,24-hour professional quotation online

The salesperson will follow the customer's requirements for the use of the product,Professionally recommend more appropriate performance and price products to customers

7. Intact packaging

Packaging according to customer needs.You can customize wooden boxes to ensure that the goods arrive at the destination in good condition

8. Various payment methods

Facilitate customer payment

9. Get good reviews from customers

Old customers have long-term cooperation,The longest is more than 7 years

10. Received various awards

Google is very recognized by us,They give us awards every year

production line

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Raw Material Smelting Workshop

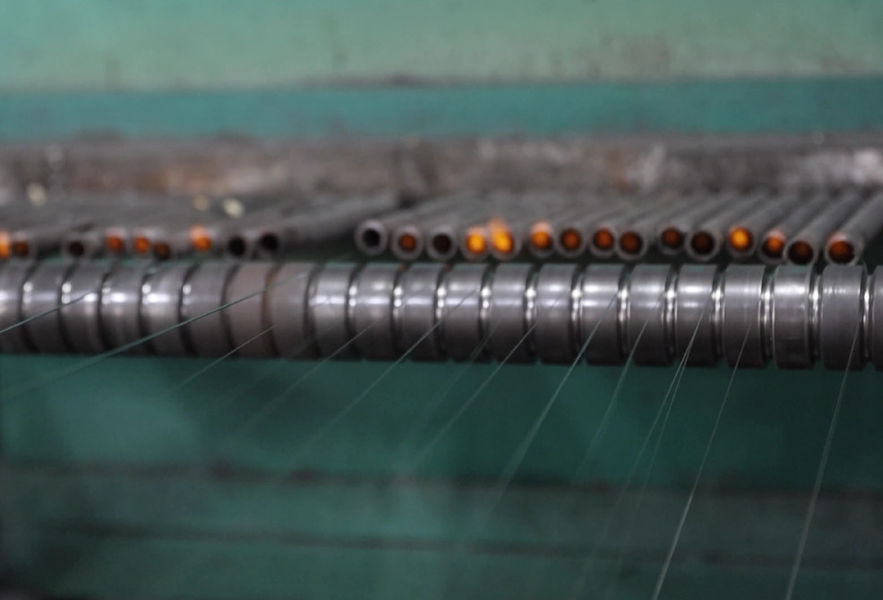

Wire Drawing Workshop

The wire drawing workshop is dedicated to the production of alloy wires. It is managed by five operators with over five years of experience and two quality control personnel. The workshop is equipped with ten German and Japanese-imported wire drawing production lines, used for cold rolling and hot drawing processes, with a monthly production capacity of 100 tons. Our technical team closely monitors and adjusts the process in real-time to ensure that the dimensional accuracy of each wire is maintained at ±0.01mm.

Metal Annealing Workshop

The metal annealing workshop focuses on the annealing treatment of alloy wires and strips to enhance ductility and tensile strength. By precisely controlling the temperature and time, we ensure that the materials perform optimally during subsequent processing. The workshop is operated by three annealing process operators who manage the furnace operations and temperature monitoring, and two quality control personnel inspect the products post-treatment. We are equipped with six Japanese-brand vacuum annealing furnaces and Swiss temperature control equipment, offering temperature control precision of ±1°C. The process is fully automated to minimize human error and guarantee that materials are heated in an oxygen-free environment to prevent surface oxidation.

Machining Workshop

The machining workshop handles deep processing of alloy materials, including precision cutting, punching, milling, and drilling operations. The workshop features four CNC machining centers from renowned brands such as DMG (Germany) and Mitsubishi (Japan). By employing CNC technology and high-precision tools, coupled with CAD/CAM systems for design and process control, we achieve processing accuracy of ±0.01mm, ensuring stable product shape and precision.

![]()